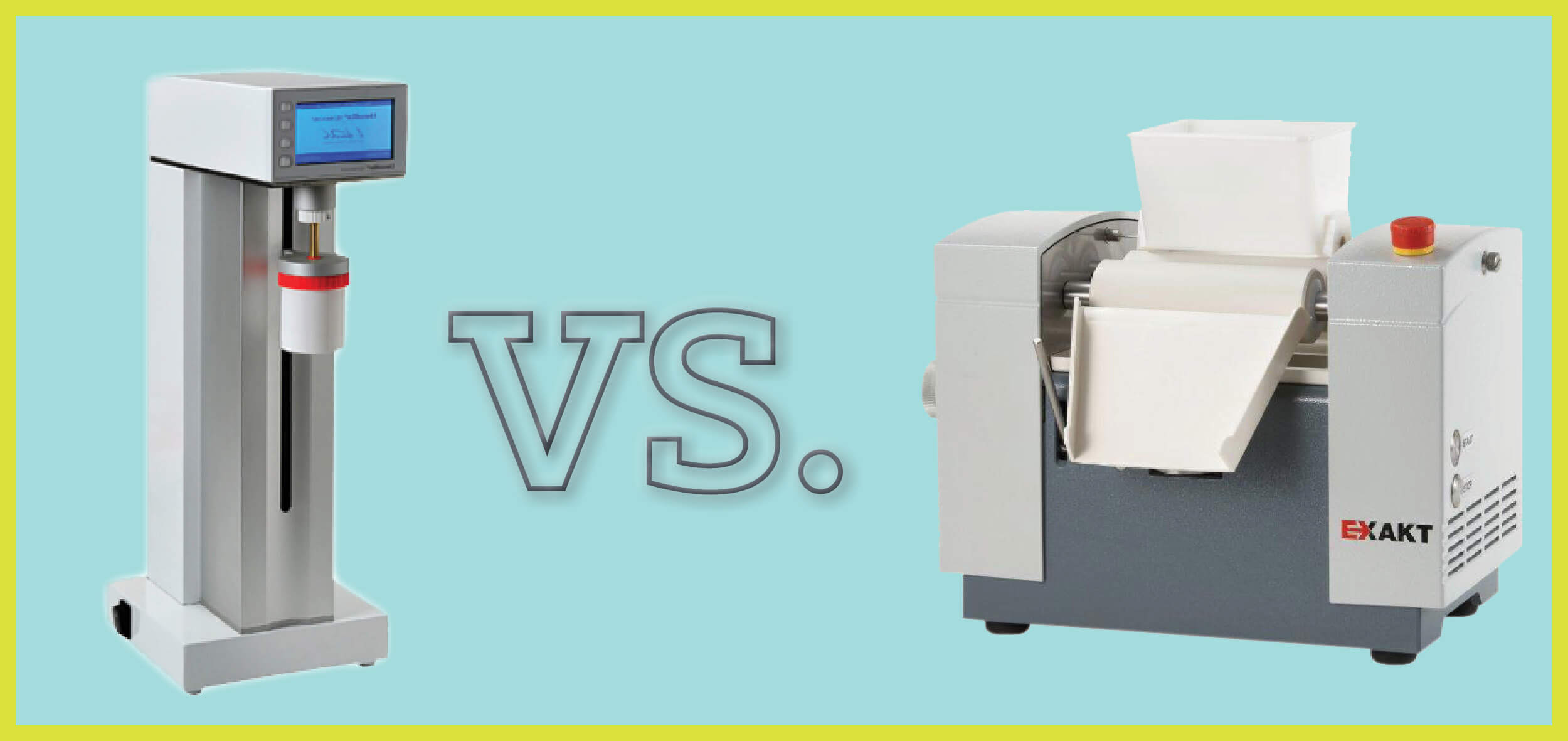

Battle of the Mixers: Unguator® vs Ointment Mill

Posted by Emily Thompson on Sep 1st 2020

One of the most frequently asked questions that we hear is, “Do I need an Unguator® or an Ointment Mill?” and, the answer is “It depends”. Let us guess, probably not the answer you’re looking for. Allow us to illustrate in a little more detail.

First, you need to have a keen understanding of what each of these units actually does. There are other factors that will influence your decision as well, such as budget, ingredient(s) in the compound and skillset. For now, let’s focus on the capabilities of each machine and the role they can play in your compounding program; this should assist you with your decision.

When you are looking for automation, go for the Unguator®. It is a workhorse that can be utilized to increase the output of your topical compounds. This machine can produce dozens of mixtures in a day that would take a compounder much longer to do by hand. The enclosed jar system prevents cross-contamination and exposure to harmful chemicals in the mixture. This added benefit is superseded only by the design of the Standard Mixing Blade. As it spins inside the jar, the S-shaped blade pushes the cream outwards to the wall of the jar where it is met with a forceful, shearing effect by the paddle on each end of the blade. This process is repeated throughout the cycle to create a homogenous and smooth mixture.

That being said, there is no unit that can reduce the particle size to the extent that the three-roll ointment mill can. While the Unguator® can create great compounds, the only way to ensure that the particle sizes of the ingredients are drastically reduced is with the use of the ointment mill. This unit takes a level of skillset, caution to operate and slows production at times, but the results are unmatched.

If you are making highly concentrated topicals in excess of 10% or more, it is almost guaranteed that the use of the mill is necessary. Processing your topical mixtures through an ointment mill can increase absorption, eliminate grittiness completely and set apart your topicals from the competition as long as you master the use of this unit. The rollers of the mill are made of a very hard material that pulverizes the particles as they pass between the rollers. By adjusting the gap settings between the rollers from a few thousands of an inch to virtually nothing, only the smallest particles are allowed to pass until the larger particles are broken down and forced through. This effect is so efficient, that it can actually separate your mixture which is why it is strongly advised to process the compound through another mixing phase prior to dispensing.

Ideally, the Unguator® and Ointment Mill should be paired together to acquire the best of both worlds. You will without a doubt notice a sharp increase in the output and quality of your compounds. As respected professionals, compounders can utilize the sophistication of these units to obtain results that are simply impossible to gain manually. Make use of this pairing to deliver the best possible compounded products to your patients.

Let’s be social! Are you following us on Facebook, Twitter and LinkedIn? We’ve got tips for how to navigate changes in the industry and killer deals on pharmacy supplies. Check us out!